Hangzhou FulltimeRobotics Co., Ltd. (hereinafter referred to as "FulltimeRobotics") recently announced that after nearly a year of meticulous research and development, iterative optimization, rigorous validation, comprehensive testing, and actual engineering applications, it has officially launched four new products for indoor painting construction robots. These products not only meet the demands of commercial applications but will also further enhance the level of automation in construction. They solidify FulltimeRobotics' business positioning and achieve full-scenario and full-process coverage in the niche market of painting construction robots, helping the company become the leading brand in this segment.Compared to other construction robot applications, indoor painting engineering has a higher degree of standardization, continuous working surfaces, and a larger overall market space. Some institutions predict that painting construction robots will be the first category of robots to achieve mass application.

The products launched by FulltimeRobotics this time include:

3.2-meter Fully Automatic Residential Scene Putty and Latex Paint Spraying Robot

3.2-meter Fully Automatic Putty Scraping and Grinding Robot

6-meter Putty and Latex Paint Spraying Robot

The Latest Robot Collaborative Management Platform

The launch of these products will comprehensively upgrade FulltimeRobotics' product matrix for indoor painting construction robots. With a richer selection of arm lengths, simpler and more convenient operation methods, and more precise cost control, they offer better solutions for industry clients.

01

The Putty and Latex Paint Dual-Function Spraying Robot (3.2-meter model) is widely applicable to residential building decoration scenarios such as commercial housing, affordable housing, dormitories, and apartments. It can perform spraying operations for various building materials, including putty, latex paint, oil灰, and interface agents, by simply and quickly changing nozzles.

This robot is compatible with BIM model import, manual modeling import, and can also automatically model on-site to generate its own working path. Based on proprietary indoor navigation, positioning, and motion control technologies, it achieves one-click fully automatic spraying operations, ensuring uniform coating without color differences and high-quality delivery. Its proprietary multi-degree-of-freedom robotic arm design allows flexible operations in narrow spaces such as corridors and foyers, meeting the automation construction needs of residential buildings.

In terms of work efficiency, the robot's putty spraying can achieve an efficiency of 600㎡/day, which is 5-6 times that of traditional manual work, significantly reducing construction time. The latex paint spraying efficiency is 1500㎡/day, with noticeably better spray quality than manual work.

02

The Putty and Oil Scraping and Grinding Dual-Function Robot (3.2-meter model) integrates the functions of scraping and grinding putty and oil. It is widely used in residential building decoration scenarios such as commercial housing, affordable housing, dormitories, and apartments.

This robot uses proprietary high-precision force control sensors and algorithms for walls and ceilings, which can adaptively control the appearance quality of scraping and grinding, achieving high-quality process requirements for putty and oil. During operations, it can automatically generate working paths through BIM model import, manual modeling import, or on-site automatic modeling by the robot. It navigates autonomously and works unmanned, significantly reducing the health risks of high-dust environments during grinding.In terms of work efficiency, the scraping efficiency is 400㎡/day, with a noticeable improvement in the appearance quality of putty and oil. The grinding efficiency is 600㎡/day, which is three times that of manual grinding.

03

The Putty and Latex Paint Dual-Function Spraying Robot (6-meter model) is widely applicable to large-space scenarios such as underground garages, factories, stadiums, and transportation hubs, performing high-altitude spraying operations for putty and latex paint.This robot uses proprietary high-precision robotic arm trajectory control technology to effectively improve construction quality. With automatic mixing and material storage spraying vehicles, it significantly reduces the difficulty of using the robot, making it extremely convenient to operate. Construction workers can quickly learn and start using it on-site.In terms of work efficiency, the putty spraying construction efficiency is 1200㎡/day, which is 10-12 times that of manual construction. The latex paint spraying construction efficiency is 2500-3000㎡/day, which is twice that of manual construction.

04

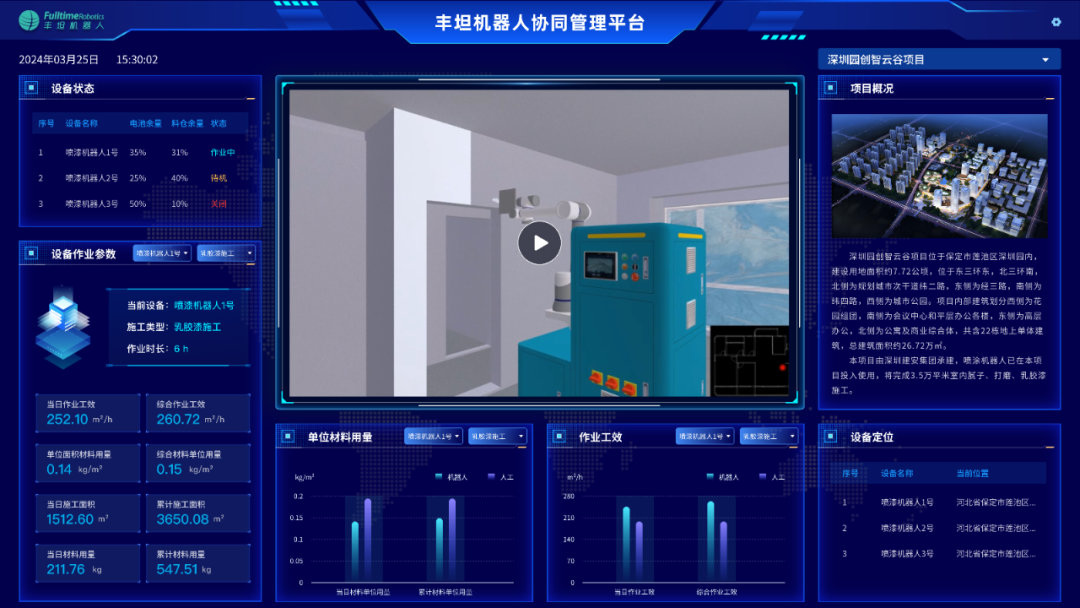

In addition to the three construction robots, FulltimeRobotics also launched the "Robot Collaborative Management Platform" to address the challenges of managing multiple robots on construction sites and the fragmentation of information. By real-time collection of data such as robot location, working status, battery level, daily construction time, construction area, and material usage, the platform presents all basic and operational data of on-site robots in a visual dashboard format. Project managers can promptly understand the comprehensive efficiency of robots each day, analyze construction efficiency, and bridge the "last mile" of intelligent construction.

Currently, FulltimeRobotics has successfully validated the commercial application of the 4.6-meter putty and latex paint spraying robot. The launch of these new products will help the company achieve full-process coverage from putty spraying, scraping, grinding, dust collection to latex paint spraying in the field of indoor painting construction. With 3.2-meter, 4.6-meter, and 6-meter models, it will achieve full-scenario coverage, further solidifying FulltimeRobotics' business positioning of "full-process, full-scenario" coverage in automated painting construction.

Looking ahead, FulltimeRobotics will continue to focus on the research and application of painting construction robots, continuously improving the intelligence level and cost-performance ratio of its products. It will deepen its expertise in the niche market and become the first brand in painting construction robots that customers are satisfied with.